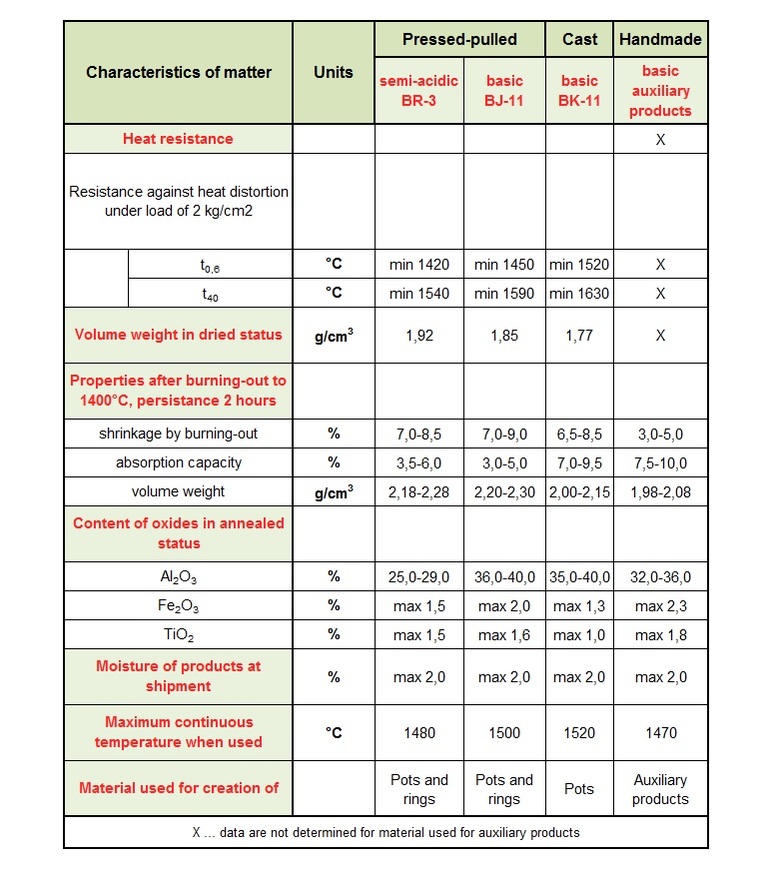

Essential chemical/technological properties of pot materials

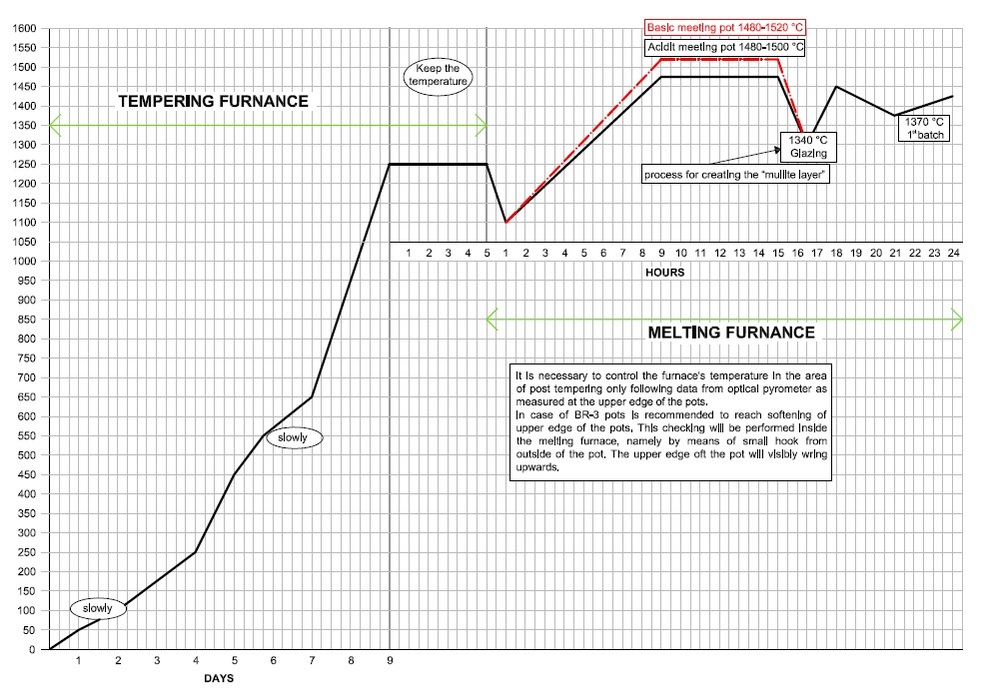

Regardless of material type, the pots will be post-tempered in the melting furnace at least for the duration of 6 (six) hours at the temperature of 1480 – 1500°C.

Tempering curves for screw-stirrers and pots of diameter up to 500 mm

(for large sketch in new window click on the picture)

Tempering curves for pots type BR 3, BJ 11, BK 11 with diameter over 500 mm

It is necessary to control the furnace’s temperature in the area of post tempering only following data from optical pyrometer as measured at the upper edge of the pots. In case of BR-3 pots is recommended to reach softening of upper edge of the pots. This checking will be performed inside the melting furnace, namely by means of small hook from outside of the pot. The upper edge oft the pot will visibly wring upwards.

The Tempering – 9 days in Tempering furnace/ 216 hours / !!

4 days: 0-250 ° C / slowly – over an hour about + 2.6 ° C / = 96 hours

30 hours: 250-500 ° C / – over an hour about +8.3 ° C /

42 hours: 500-650 ° C / SLOWLY – over an hour about +3.6 ° C /

2 days: 650-1250 ° C / over an hour about +12.5 ° C /

At the end of the process in Tempering furnace, it is very important to keep the pot at 1250°C for at least 9 hours !!!

Then there is a rapid shift to a smelter, where continue according to curve.